February 20, 2022

Although they are most often found in factory settings, conveyor products (both the device and the things conveyed) have become an integral and familiar component in a great many automated facilities that we encounter on a regular basis. As far back as when we were children, who has not been fascinated by the clever yet simple brilliance of the grocery store’s checkout counter conveyor belt? And what grade-schooler has not understood intuitively the vast labor-saving aspect of that most iconic of commercial conveyor inventions—Henry Ford’s automobile assembly line?

At present, Framing Tech offers three basic conveyor product design models (more on those in a moment). Before discussing those, however, we believe it would be helpful to prospective customers to understand what factors to consider when shopping for any conveyor product.

First: What Do We Mean by “Conveyors”?

By definition, the primary purpose of conveyors is to move individual items or bulk material from one place to another. They can also serve as key material-handling avenues to improve throughput and efficiency. Technical advances in materials (such as aluminum), controls, and modular sub-components have made possible a wide range of conveyor designs, from mini conveyors for discrete sorting to large conveyors for bulk material transport—and everything in between.

Because so many types of products are moved on conveyors, these devices come in a wide array of shapes and sizes, ranging from ones with widths of less than two inches for moving extremely small, delicate

parts to others that are several feet wide.

When Shopping for Conveyor Products, Always Ask the Right Questions

Given such a vast array of possibilities, the wisest approach is to ask a series of well-considered questions.

Select a conveyor by first asking, “What type of product is the application moving?”

Conveyors for material handling of bulk product tend to be more rugged than those for moving smaller individual items. The latter, by contrast, require conveyors that can transport items with greater precision.

How does nearby furniture or equipment interact with the product being transported on the conveyor?

To answer that question, we divide conveyors into four different classes, as follows.

Conveyor class 1 is the simplest and includes material-handling uses in which the conveyor serves as a conduit to transport bulk product or individual items in a steady stream with little interaction along the way.

Class 2 covers conveyor devices that act as bridges to take product or items from one location or machine to another.

Class 3 conveyors are ones that take materials into or out of machines or stations.

Class 4 includes conveyors that run right through machinery without break.

The first two classes generally prioritize ruggedness or throughput; whereas the last two classes require accurate positioning and, in many cases, specialized pucks (transport buckets or product carriers) to steady product while machines perform work on the product pieces, so as to prevent the product from falling over during transport or processing.

What is the maximum weight of the product being moved?

Does a conveyor need to operate at a certain speed?

Does the application need the conveyor system to have inclines, declines, or curves?

If stabilization is important, look for conveyor features that secure the material or product onto the conveyor, or enclose it.

Will moisture be present in the application?

Does the application need to be sanitary?

If the answer to these questions is YES, look for rugged or washdown-rated conveyors with open frames. Most conveyors in light- and medium-duty discrete transport applications use a belt that’s wrapped around two or more pulleys. A motor powers the pulleys, which in turn engage the conveyor belt.

There are numerous belt styles and materials to meet specific application needs. Some belts are low-friction, which allows product items to slide a bit for eventual accumulation at a certain point. On the other hand, high-friction belts have more grip to better hold products. Engineers can design such conveyors to meet exact application specifications.

Lastly, be aware that a great deal of engineering expertise and precision goes into designing a truly practical and efficient conveyor—as this video on the manufacture of roller conveyors illustrates:

Specialty Conveyor Transport Types

The most familiar type of conveyors are belt conveyors, which use a continuous belt in a loop to convey products or material; roller conveyors (powered and non-powered), which use parallel rollers mounted in frames to convey product by either gravity or inertial force; and interleaved metal plate conveyors, such as one finds commonly in airport luggage retrieval areas.

Yet there are many other specialty types, such as:

- Slat/Apron

- Ball Transfer

- Magnetic

- Bucket

- Chute

- Drag/Chain/Tow

- Overhead

- Pivot

- Pneumatic/Vacuum

- Screw/Auger

- Timing

- Vacuum

- Vertical

- Vibrating

- Walking Beam

- Wheel

For example, magnetic conveyors are built with ceramic magnets for applications needing parts to adhere to the belt during processing or for jobs that require elevation changes. Higher magnet strength serves inverted applications. Vacuum conveyors work with a perforated belt that draws air through grooves in the conveyor bed plate to hold light or flimsy parts on inclines or during especially fast transport. Timing belt conveyors use toothed belts that engage synchronous drive pulleys while serving as the conveyor surface as well, thus providing excellent belt movement control for accurate part or fixture positioning. Where metal scanning equipment checks product (usually food) for contaminants, metal-free conveyors with polymer bed plates are used.

Last but not least, pivot conveyors mount to a base to swing away when workers need to walk through a conveyor line. Some controls can automatically resume product flow after the conveyor returns to the in-line position. Where the conveyor takes the form of a timing belt conveyor, servo drives accurately stop and start the setup to provide precise part location. They also let engineers control acceleration on assembly line conveyors. For extra-wide items needing transport, single-drive multi-belt conveyors serve two or more lanes of product for the sake of efficiency.

But Tell Us About Framing Tech’s Conveyor Products!

We now offer a wide range of belt conveyor products that can be tailored to your specific product conveying needs!

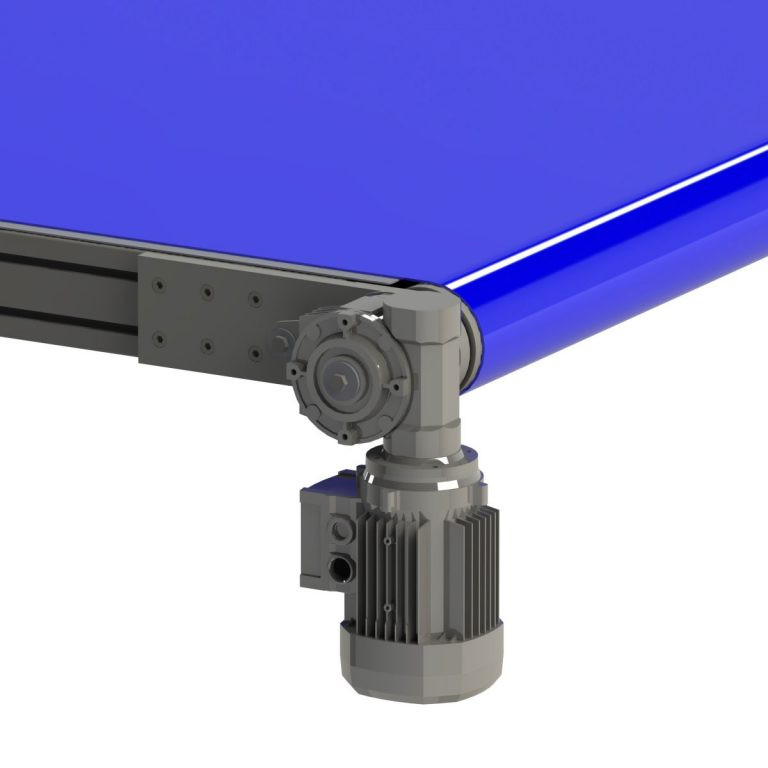

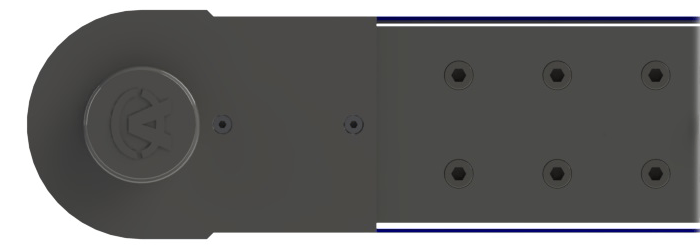

Our extruded aluminum T-slot framing system allows for customized designs created to fit your particular production area and production needs. We work with industry-leading belt and motor manufacturers to offer you the highest-quality components. Our three main belt conveyor models allow for a wide range of applications.

20 Series Conveyors

(Light Duty)

This short and/or narrow conveyor system is lightweight and ideal for carrying small components. It uses direct drive systems only. We have three belt widths available for this series: 80mm, 130mm, and 180mm. The operational length of a 20 Series conveyor is between 400mm and 2,500mm.

50 Series Conveyors

(Standard)

One of our most popular and versatile conveyor models, the 50 Series conveyors will be able to tackle most of your conveying needs. The 50 Series conveyors are available with both direct drive and central drive options. We have belt widths available in 50mm increments from 100mm to 500mm, as well as custom sizing options. The length for 50 Series flatbed belt conveyors is between 500mm and

6,000mm.

95 Series Conveyors

(Heavy Duty)

Intended for heavy-duty conveying needs, this system uses our rugged 45mm × 90mm profile, which has a large carrying capacity and prevents any issues when transporting high-load items and materials. Similar to the 50 Series conveyors, 95 Series conveyors are available in direct drive and central drive configurations. We carry belt widths in 50mm increments between 200mm and 1,000mm, as well as in custom sizing options. The 95 Series conveyors are available in lengths of 700mm–6,000mm.

Click here to learn more about our conveyor products

or to get a quote!